Most copper and brass radiators just need a clean surface and some solder to repair. Before you can repair the aluminum radiator , you need to find the leak. Once the leak is found the aluminum radiator must be cleaned for the epoxy to take hold.

You need to be very careful because epoxy is a chemical and very dangerous. Aluminum radiators are hard to weld which makes epoxy the best most inexpensive way to fix them. Best epoxy for aluminum repair I always keep some in my service shop. My trail fix was to fill the damaged areas with RTV and pinch them off.

To repair an aluminum radiator with epoxy , turn the engine off, allow it to cool down and take out the radiator. Stic-Tite is a plastic string that works like solder. Find the leak, and clean the area around it thoroughly. Take the amount of epoxy needed to fix the leak, and knead it in your fingers until it becomes soft.

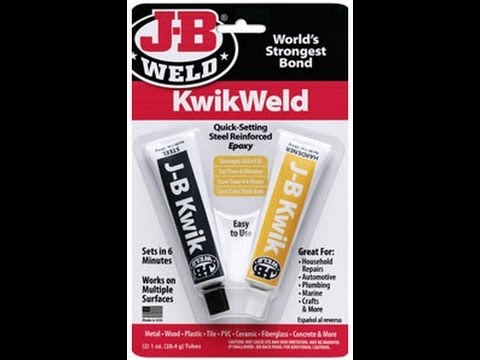

JB Weld epoxy products bond strong to a variety of surfaces in even the toughest environments.

Made in the USA for more than years. We know our parts and products. JB is a bit of a long shot for that repair. Heat Exchangers Made with Aluminum Brazing vs.